- Your cart is empty

- Continue Shopping

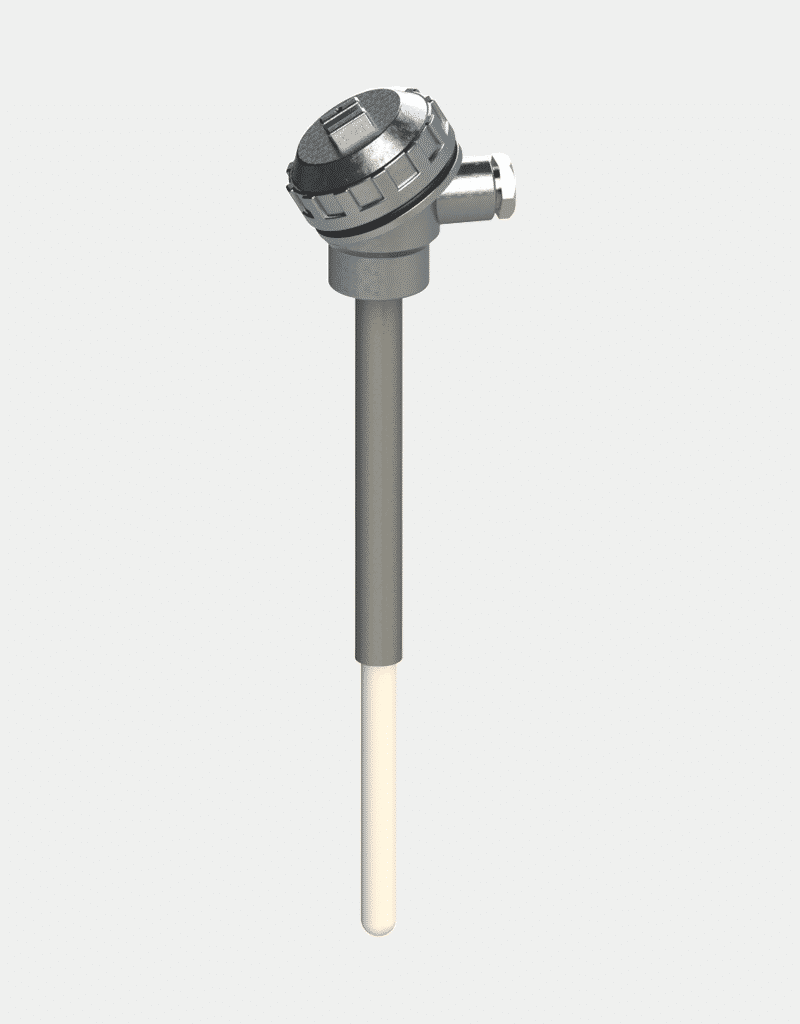

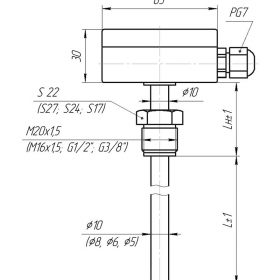

High-temperature ceramic sensor ТХА-021, ТХК-021, ТЖК-021

Price range: 2180 ₴ through 2600 ₴

High-temperature sensors of ТХА-021 modification are used to change the temperature of objects up to 1200 ° С.

High temperature ceramic sensor THA-021, THK-021, TJK-021 are designed to measure temperatures up to 1200 ° C.

The sensors allow measuring the temperature of gaseous and chemically non-aggressive media to the material of protective fittings.

Temperature is the most common measured parameter, and overheating is one of the most negative factors in the operation of equipment, therefore, there are a huge number of ways and places of using temperature sensors.

How the thermocouple works

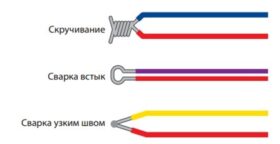

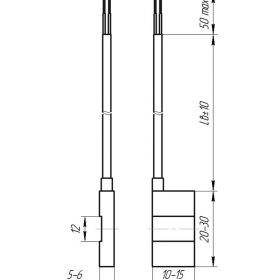

The operating principle of the thermocouple is based on thermoelectric Seebeck effect... The thermocouple has two soldered ends, one end is placed in the measuring environment and is called a working or hot junction, and the other end, at the point of connection to the device input, is a cold junction. Methods for manufacturing a hot junction are shown in Figure 1. When a temperature difference between the hot and cold junction occurs in the circuit, a thermo-EMF occurs, the value of which is fed to the input.

Picture 1 - Hot junction manufacturing methods

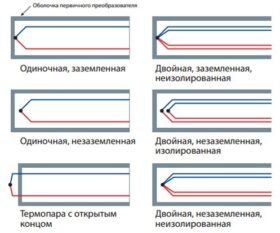

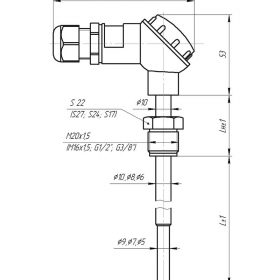

The working junction of high-temperature sensors is placed in protective fittings. Thermocouple junctions are manufactured in various configurations. Junctions can be grounded or ungrounded, and two-element thermocouples can be insulated or uninsulated. Hot junction configurations are shown in Figure 2.

Figure 2 - Hot junction configurations

A grounded thermocouple junction is formed when a thermocouple junction is connected to the sensor sheath. Grounded junctions have better thermal conductivity, which in turn improves response times. However, grounding also makes thermocouple circuits more susceptible to electrical noise, which can distort the thermocouple voltage signal if the tester does not provide isolation. All high quality transmitters and I / O boards are electrically isolated as standard. The grounded junction is also more susceptible to chemical contamination over time.

Open junction thermoelectric converters have a hot junction protruding from the sealed end of the sheath, providing high response times. Sealing prevents moisture or other contaminants from entering the shell. Typically, these thermocouples are only used in non-corrosive gases such as air ducts.

Ungrounded junctions are obtained when the thermocouple elements are not connected to the sheath of the primary transducer, but are surrounded by insulating powder.

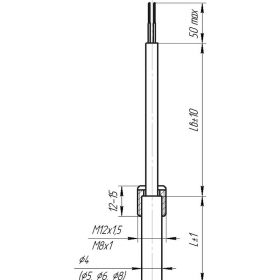

Features of the high-temperature ceramic sensor ТХА-021, ТХК-021, ТЖК-021:

- It has a terminal head that allows you to conveniently connect the cable to the sensor and protect the connection.

- Short-term operation of the sensor is possible at 1200 ° C.

- The model is not high temperature along its entire length, so only the ceramic part should be in the hot zone.

- During installation and operation, it is necessary to avoid impacts of the thermal converter, since part of the protective fittings is made of ceramics.

- Not applicable for measuring the temperature of liquids, as well as in aggressive gases - evaporation of acids, alkalis.

Additional Information

| NSX type | |

|---|---|

| Head type | |

| Mounting part diameter D, mm | |

| Mounting part length L, mm | |

| Thermal inertia index, s | |

| Working range of measured temperatures, ° С |

You must be logged in to post a review.

Reviews

There are no reviews yet.