- Your cart is empty

- Continue Shopping

$1466

Electromagnetic flow meter ERS-50 is designed to measure the average volume flow, volume, dosing of liquid media with a specific electrical conductivity from 10-3 to 10 cm / m: water, milk, dairy products, fruit juices and other food components, as well as acids, alkalis and pulps in technological processes and in commercial calculations. Accuracy class - 0.5.

Flowmeter-counter electromagnetic ERS-50 (ERS-50 flow meter) (NIO-35) is designed to measure the average volumetric flow rate and volume of various liquid media with specific electrical conductivity from 10 to 10 Cm / m.

ERS-50 flow meters can be used in food, milk processing and other industries for commercial purposes, as well as in various technological processes.

Principle of operation Flowmeter-counter ERS-50

The principle of operation of electromagnetic flow meters ERS-50 is based on the law of electromagnetic induction, which consists in the fact that when an electrically conductive liquid crosses a magnetic field, an electromotive force (EMF) is induced in it, as in a moving conductor, proportional to the average velocity of the liquid.

To implement this principle, a section of the pipeline is made of a non-magnetic material, on the inner surface of which an electrically insulating coating is applied. Two electrodes are introduced into the pipeline, located diametrically opposite to each other in one of its cross sections.

The pipeline is placed between the poles of the magnetic system, and the electrodes are located perpendicular to the direction of the lines of force of the generated magnetic field. The voltage across the electrodes (E) is described by the ratio:

E = B⋅D⋅W = 4⋅B⋅Q πD, (1)

Where IN - magnetic induction;

D - nominal diameter of the pipeline;

W And Q - respectively, average speed and average volumetric flow rate of the liquid.

The average volumetric flow rate and the amount (V) of the liquid flowing through the EMD pipeline are determined by the ratios:

Q = (Ni - НУ) ⋅λ⋅ПР + СН; (2)

V = Q⋅tж, (3)

Where Ni - code proportional to the voltage at the electrodes (E);

WELL - the initial value of the zero level of the Ni code, measured during the certification of EDS at the manufacturer, as well as during its periodic verification or calibration;

λ - coefficient calculated at the design stage;

ETC And CH - respectively, the proportional factor and zero offset, which determine the nominal static characteristic. These coefficients are determined with high accuracy at the manufacturing plant during the certification of EDS. They can be updated during operation;

tzh - fluid flow time.

To minimize the polarization of electrodes in EMD, a pulsed magnetic field of low frequency is used.

Airframe ЭРС-50

ERS-50 flow meter-counter consists of an electromagnetic flow sensor (EMF) and an electronic secondary transducer (PV), connected by a 5 m cable. The maximum possible cable length is 30 m.

The electromagnetic flow sensor consists of the following main units: measuring channel, magnetic system and housing.

A pipe made of non-magnetic stainless steel 12X18H10T GOST 9941-81 is used as the unit of the measuring channel, the inner surface of which is covered with an electrical insulating material (fluoroplastic F4D TU 6-65-1937-82).

The electrodes are made of VT 5 OST 1.90173-75 titanium. They are located diametrically opposite to each other in the middle section of the measuring channel assembly and are isolated from its wall.

The magnetic system consists of field coils and a magnetic circuit. The excitation coils are made with a copper winding wire and are placed diametrically opposite to each other on the pipeline of the measuring channel assembly.

Building pERS-50 electromagnetic flowmeter-counter made of stainless steel and welded to the piping of the measuring channel assembly.

The EMD is attached to the pipeline using a threaded or flange connection.

The secondary converter is made in an aluminum casing, consisting of a base and a cover, the seal between which is provided with a rubber gasket. The base and cover are connected together using four captive screws.

A power supply and signal conversion device board with terminal blocks for connecting a power supply, EMD and external devices is installed inside the base.

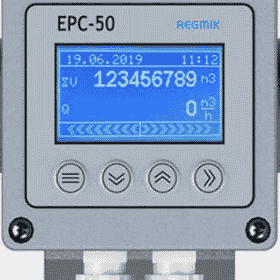

On the inner side of the cover there is a controller board with an indication unit, and its semiconductor indicator is installed in front of the transparent window. In the ERS-50 Flowmeter-Counter, the measurement results are displayed on a 9-digit semiconductor display. There is a possibility of additional installation of an external (up to 100 m) indicator, which displays the value of the current volume.

On the front surface there are three multifunctional keys, which are used to control the operating modes of the ERS-50 flow meter.

The connection between the board and the display unit is made using a cable with connectors.

ERS-50 flowmeter-counter provides high accuracy of measurements of current and total volume in liters, average volumetric flow rate in l / s and m3 / h, self-diagnostics. In the dosing mode, the ERS provides the establishment of the value of the dose of liquid flowing to control an external actuator with a voltage in the switching circuits up to 380V.

In the ERS flow meter there is an RS-232 interface for communication with a personal computer and a pulse output with adjustment from 1 to 100 imp./l. The electromagnetic flow sensor (EMF) is a straight measuring tube with a fluoroplastic coating without moving parts and protruding parts, which allows CIP cleaning with hot detergents, air purging and steam sterilization, as well as eliminating additional pressure losses.

Electromagnetic flowmeter-counter ERS-50 has a current output of 4-20 mA, which corresponds to the flow rate range from 0 to the upper limit of the measurement range.

The EMF is connected to the pipeline using a threaded flange Rd78 ST SEV 307-76, which is included in the delivery set.

ERS-50 electromagnetic flowmeter-counter provides metrological characteristics when using an air separation system, which excludes the presence of air in the medium being measured.

The operation of the electromagnetic flowmeter-counter ERS-50 at milk processing enterprises of Ukraine began in 1994.

The REGMIK enterprise releases an updated and significantly improved version EPC-50 electromagnetic flowmeter.

Download

You must be logged in to post a review.

Відгуки

Відгуків немає, поки що.