- Your cart is empty

- Continue Shopping

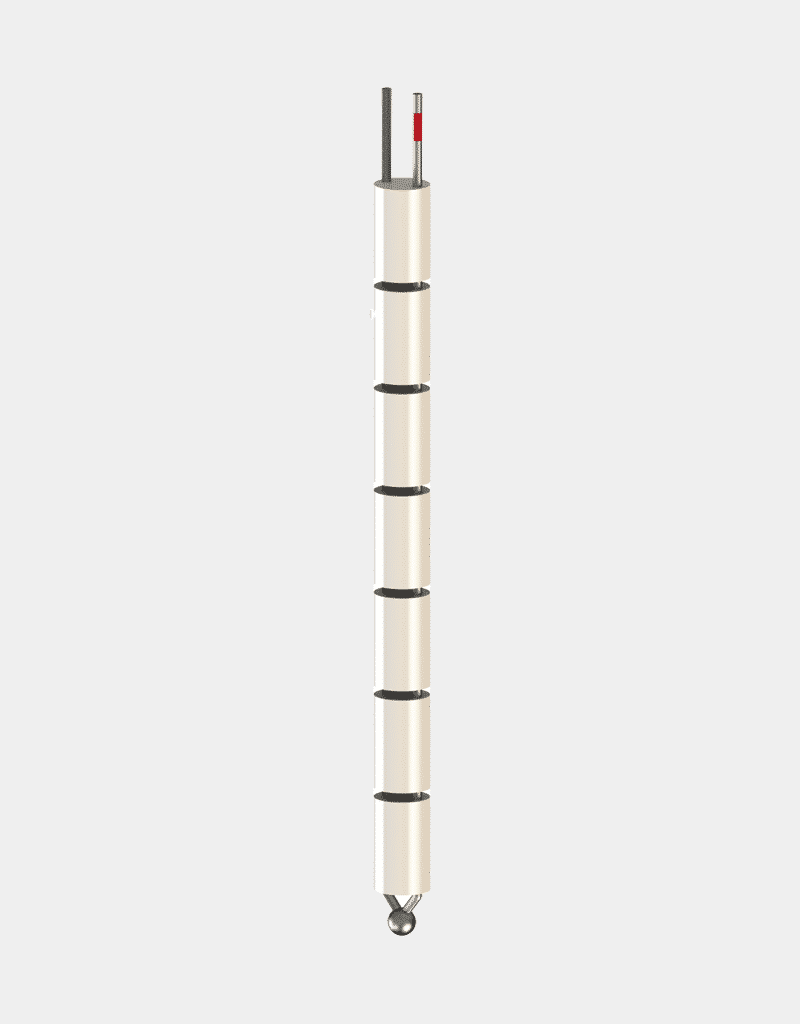

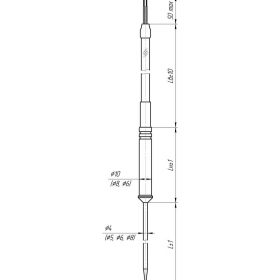

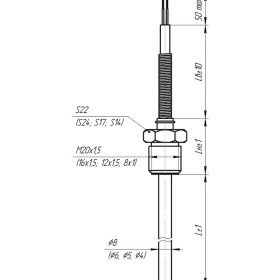

High-temperature temperature sensor ТХА-210, ТХК-210

$11

High temperature temperature sensor ТХА-210, ТХК-210 (thermocouple, thermoelectric converter, temperature sensor) is used in many industries to measure the temperature of air, exhaust gases and their combustion products and other chemically non-aggressive media in the temperature range from -40 to 1000 ° C.

High temperature temperature sensor ТХА-210, ТХК-210 (thermocouple, thermoelectric converter, temperature sensor) is used in many industries to measure the temperature of air, exhaust gases and their combustion products and other chemically non-aggressive media in the temperature range from -40 to 1000 ° C.

The range of temperatures measured by the sensors depends directly on the chemical composition of the measuring element. The main measuring element of such sensors is a piece of thermocouple wire, sequentially welded from two dissimilar electrically conductive metals, which is called a "thermocouple". In accordance with the purpose and design, thermocouple may be submerged or superficial, sealed or leaky (with or without shell), shockproof, stationary, portable etc.

Features:

- Low thermal inertia.

- Short-term operation of the sensor is possible at 1100 ° C.

- Since the protective beads are made of ceramic, it is necessary to avoid impacts of the thermal converter during installation and operation.

- Not suitable for measuring the temperature of liquids, melts containing nitric acid and nitrates, and also for use in atmospheres with a high content of sulfur and ammonia.

NSX type:

- TXA - K -40..1000 ° C

- THK - L -40..600 ° C

- TJK - J -40..600 ° C

Type K (chromel-alumel thermocouple):

- Widely used in various fields from -100 ° C to + 1000 ° C (recommended limit, depending on the diameter of the thermocouple);

- A hysteresis effect occurs in the range from 200 to 500 ° C, i.e. the readings may differ during heating and cooling. Sometimes the difference reaches 5 ° C;

- Used in neutral or oxygen-rich atmospheres;

- After thermal aging, the readings decrease;

- It is not recommended to use in a discharged atmosphere, because chromium can be released from the Ni-terminal (the so-called migration), while the thermocouple changes the TEMF and shows an underestimated temperature;

- The sulfur atmosphere is harmful to the thermocouple as it affects both electrodes.

Type J (iron constantan thermocouple):

- It is not recommended to use it below 0 ° C, as moisture condensation on the iron lead leads to the formation of rust;

- The most suitable type for a rarefied atmosphere;

- The maximum application temperature is -500 ° C, since above this temperature, the leads are rapidly oxidized. Both leads are quickly destroyed in a sulfur atmosphere;

- The readings increase after thermal aging;

- The advantage is the low cost.

Tolerance class:

- TXA - 1,2,3

- THK - 2.3

- TLC - 1.2

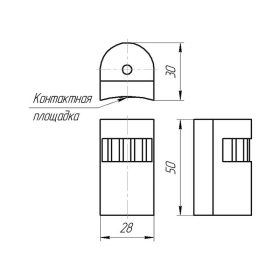

Possibility of execution with terminal block THA-210k

Additional Information

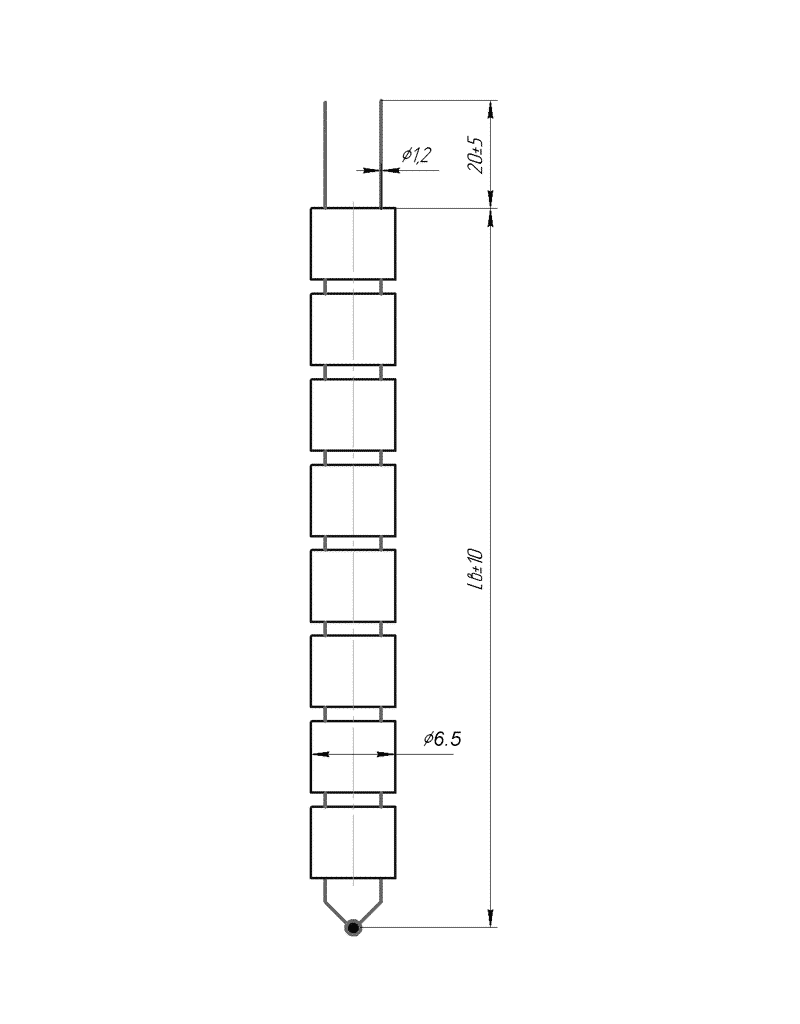

| Dimensions | Н/Д |

|---|---|

| NSX type | |

| Tolerance class | |

| Working range of measured temperatures, ° С | |

| Thermal inertia index, s |

You must be logged in to post a review.

Відгуки

Відгуків немає, поки що.