- Your cart is empty

- Continue Shopping

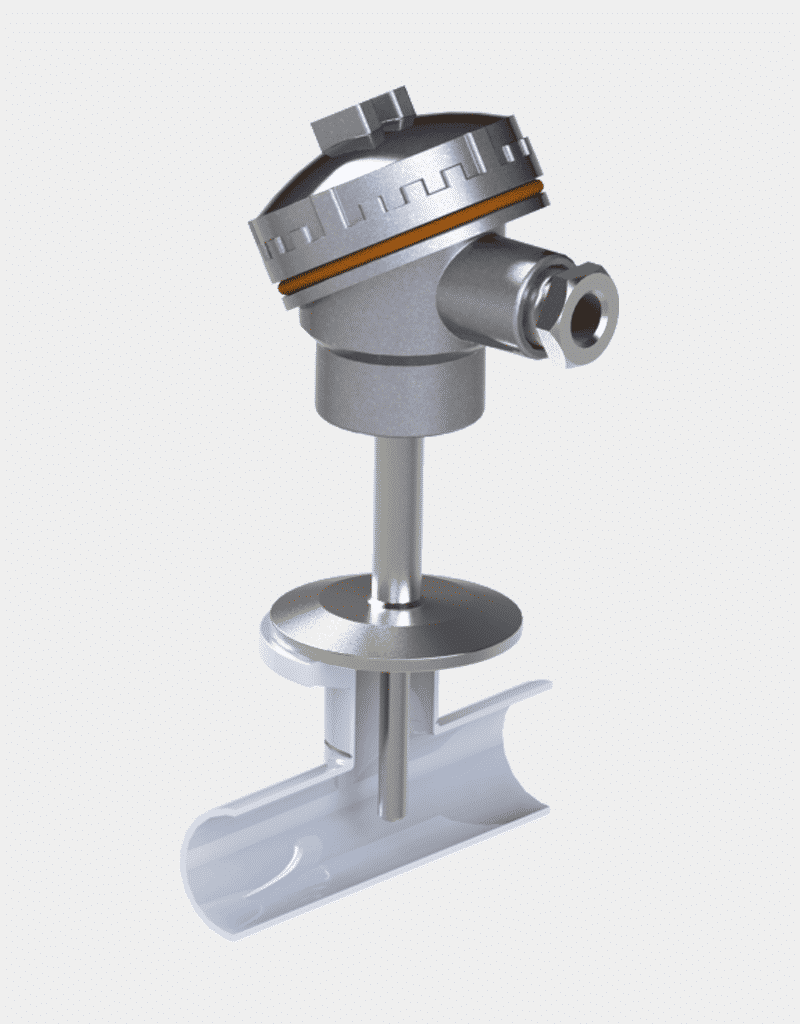

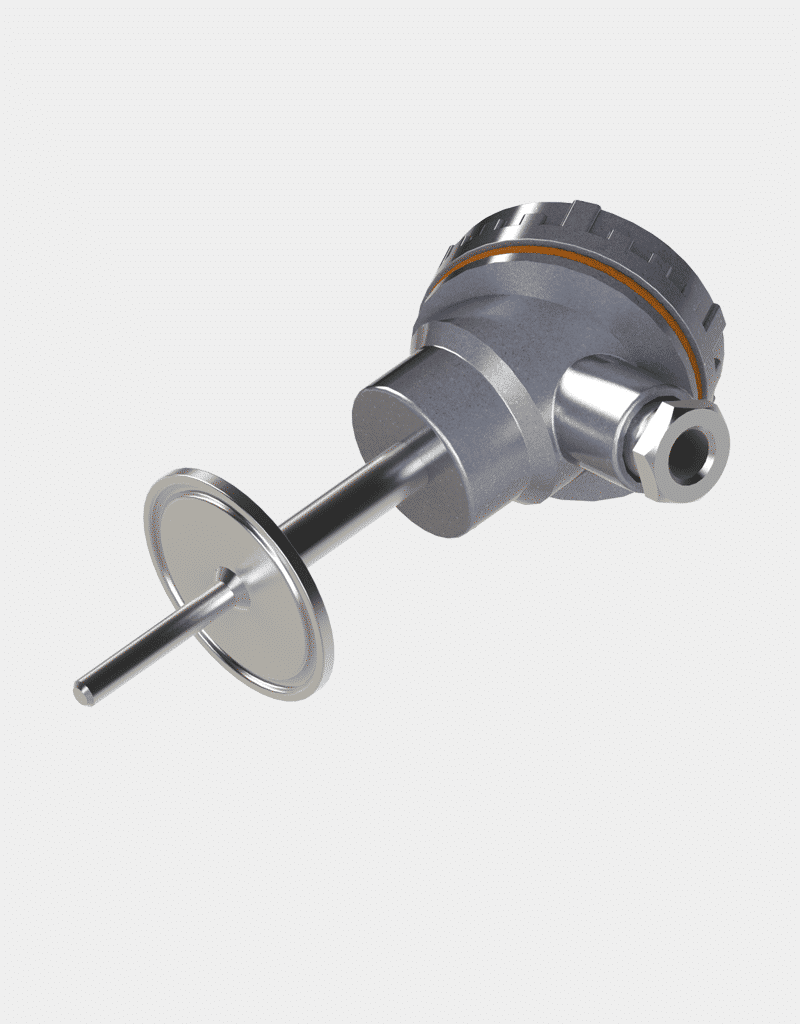

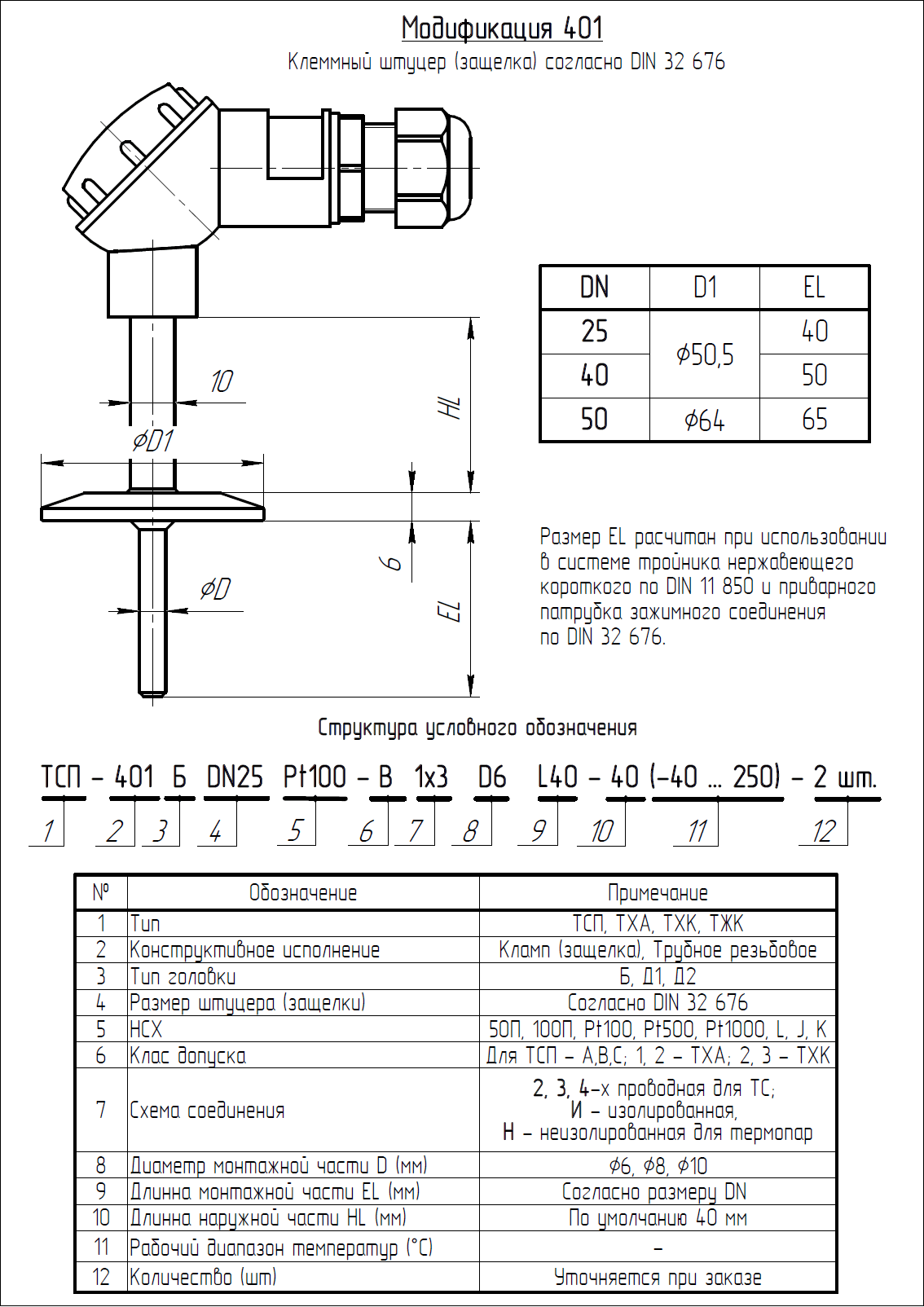

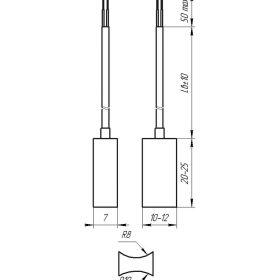

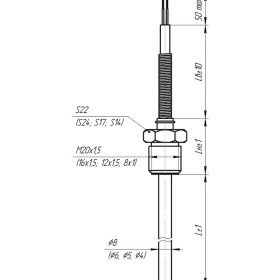

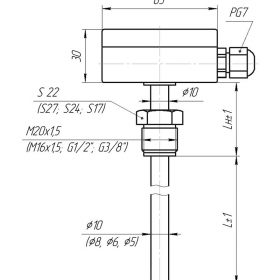

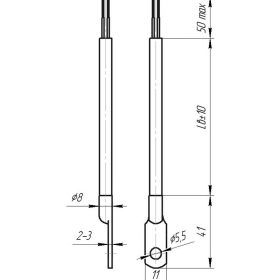

Sensors for the food industry 401

Price range: 1065 ₴ through 1703 ₴

Terminal socket (latch) according to DIN 32 676.

Possible execution of sensors with tolerance class B (standard), with class A +60.00 UAH.

Sensors for the food industry 401 are used in the food and pharmaceutical industry in accordance with the hygiene standard DIN 32 676.

Temperature is the most common measured parameter, and overheating is one of the most negative factors in the operation of equipment, therefore, there are a huge number of ways and places of using temperature sensors.

The principle of operation of resistance thermocouples is based on a change in the electrical resistance of conductors and semiconductors depending on temperature. The material from which such a sensor is made should have a high temperature coefficient of resistance, possibly a linear dependence of resistance on temperature, good reproducibility of properties and inertness to environmental influences. To the greatest extent, platinum satisfies all of the above properties; slightly less copper.

Thermocouple Are exclusively differential temperature sensors. They generate an electrical signal proportional to the temperature difference between two different points. Therefore, the junction (junction) that we use to measure the required temperature is called the "hot" junction, while the other junction (from which we can not escape) is called the "cold" junction.

Terminal head material for food grade sensors 401

- Standard connecting head made of AG-4V press material with PG13.6 sealed lead-in;

- Enlarged connecting head made of AG-4V press material with PG13.6 sealed gland (when ordering, designation B);

- Connecting head made of cast aluminum, KSC form (when ordering, designation D1);

- Connecting head made of cast aluminum, KSE form (when ordering, designation D2);

Type of attachment to the working environment - terminal nipple (latch).

Connection diagrams - 2, 3 or 4 wires.

Sensor types - 50P, 100P, Pt100, Pt500, Pt1000, L, J, K.

Temperature range -40 ... + 250 ° C.

Number of sensing elements (for RTDs) 1 or 2.

Thermometers for the food industry can be conical union

Additional Information

| Head type | |

|---|---|

| Plug type | |

| NSX type | TSM 50M, 100M, TSP 50P, 100P, RTD Pt100, Pt500, Pt1000, TXA, THK, TJK |

You must be logged in to post a review.

Reviews

There are no reviews yet.