- Your cart is empty

- Continue Shopping

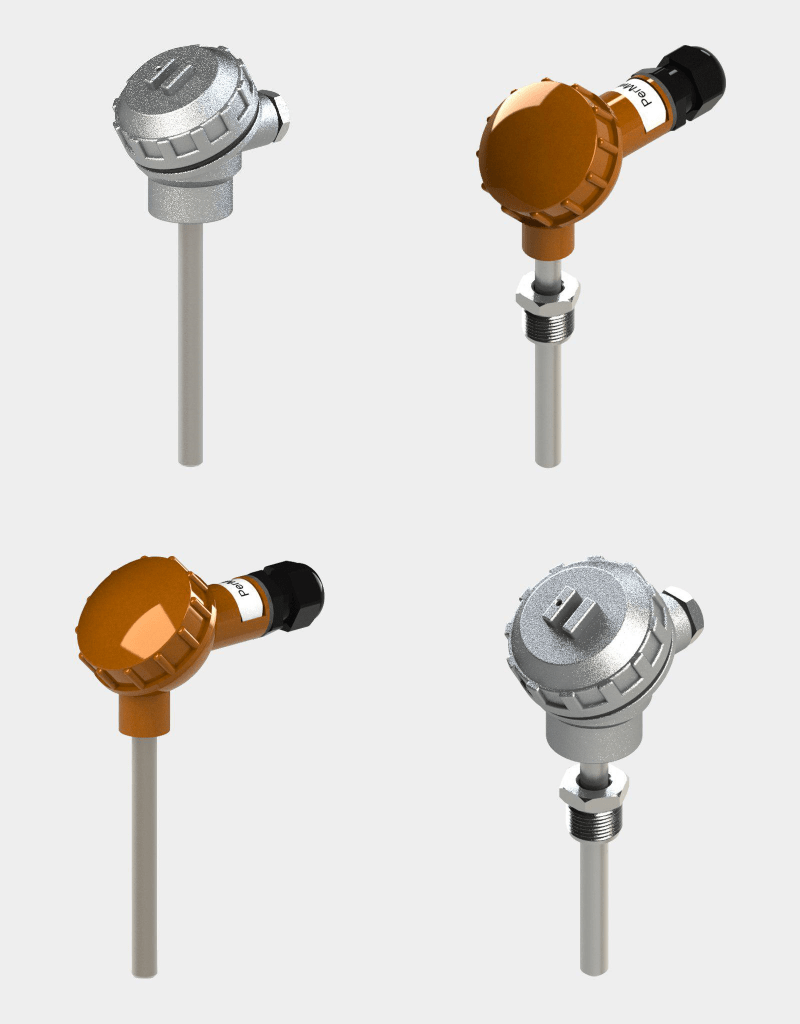

Thermoelectric temperature transmitters with a unified output current signal 4-20 mA

Thermoelectric converters (temperature sensors) REGMIK-PTU-THAU, REGMIK-PTU-TKHKU, REGMIK-PTU-TZHKU (hereinafter PTU) are designed to convert the temperature of the working end of the thermocouple into thermo-EMF. PTU is used to measure the temperature of liquid, bulk and gaseous media that do not contain substances that interact with the material of the protective fittings and the connecting cable.

The area of application of the PTU is a system for monitoring and regulating the temperature of technological processes in various areas of industry, agriculture and communal services, and everyday life.

The principle of operation of the PTU is based on the Seebeck thermoelectric effect. The thermocouple has two soldered ends, one end is placed in the measuring environment and is called a working or hot junction, and the other end, at the point of connection to the device input, is a cold junction. When there is a temperature difference between the hot and cold junction in the circuit, a thermo-EMF occurs, the value of which is fed to the input. The working junction is placed in a protective armature.

Main technical characteristics of vocational schools:

- Measuring element connection diagram - two-wire;

- Thermocouple type - K, L, J;

- The material of the protective fittings is stainless steel 12x18N10T;

- Dust and water protection degree - IP54;

- Construction - non-separable;

- Insulation resistance - at least 100 MOhm;

- Operating temperature range, depending on the type of thermocouple - (0-1100) С;

- Output signal - 4-20 mA;

- DC supply voltage - 9-36 V;

- Consumption current, no more - 40 mA;

- Limit of permissible value of basic error, no more - 0.5; 1%.